How to build end-to-end lot and serial traceability that speeds audits.

What traceability means across design to shipment

Traceability connects parts, processes and people to every finished unit. In regulated environments it is a core requirement, not a nice to have. The goal is simple. You should be able to answer what was made, with which components, under which conditions, by which operators and where it went.

That chain supports product quality, customer trust and compliance. Standards bodies and agencies frame the need in different ways, yet they point to the same outcomes. ISO 9001 emphasizes documented information that proves your system does what it claims, which includes records that support product history. For firearms manufacturers, federal rules require specific production and disposition records that enable trace and audit. The ATF maintains guidance and regulations for licensed manufacturers at ATF Recordkeeping. Beyond any single rule, manufacturers benefit when the digital thread carries genealogy from design through shipment. NIST’s programs discuss how data linking and traceability improve supply chains at Traceability and Data Linking.

ERP workflows that simplify compliance evidence

An ERP designed for manufacturing can embed traceability into normal work so compliance evidence appears as a byproduct. When engineering releases a revision, the system attaches the version to the BOM and routings. When material is received, barcodes tie lot and serial details to supplier, date and certs. As jobs move, labor capture and backflushing link operators, machines and consumption to each lot. Quality checks record results at critical control points. Shipments record where each lot or serial went with packing and carrier data.

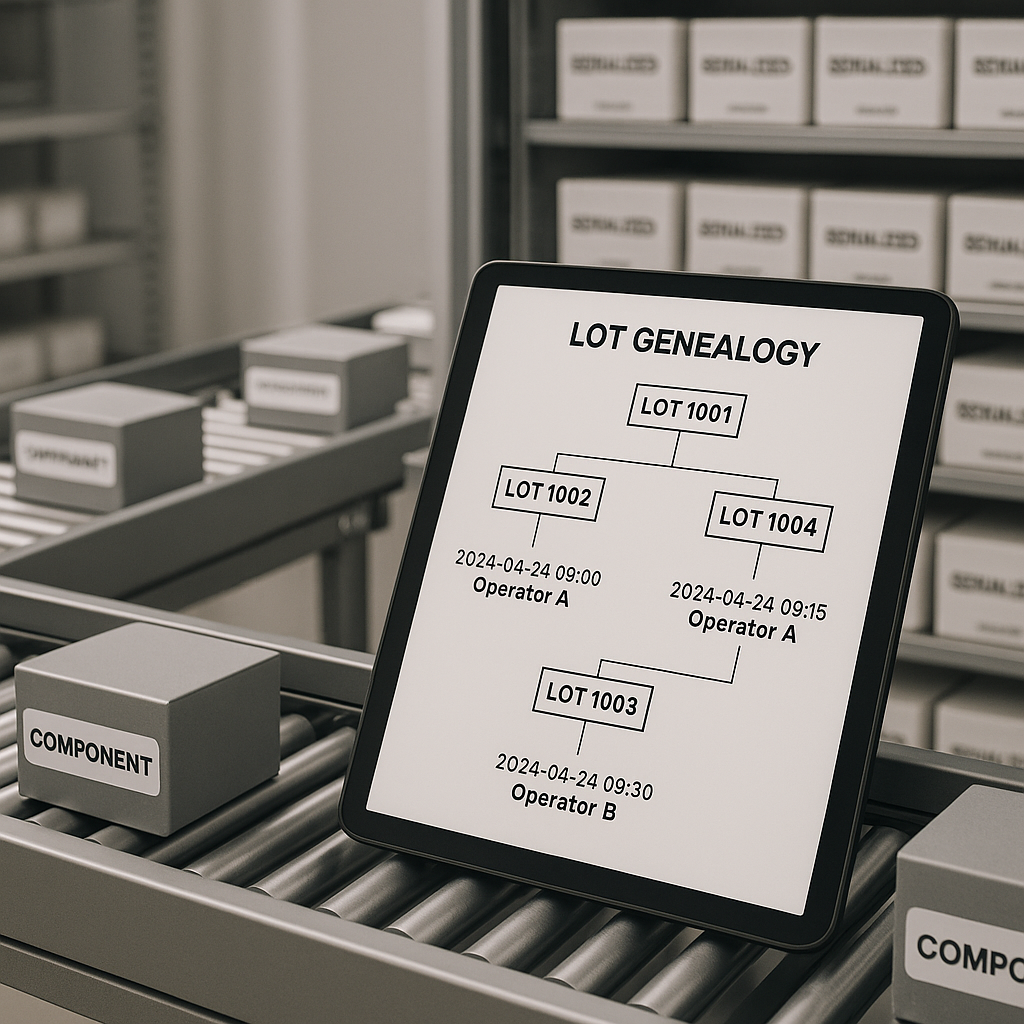

With those pieces connected, you can build a genealogy view that flows from finished unit back to raw material in one click. You can also search forward from a suspect batch to all affected customers. Audits become faster when every record lives in one system that shows who did what and when. This improves customer confidence and reduces recall risk. Keep screens simple for operators so scanning is quick and accurate. Use mobile devices on the floor and at the dock so data enters at the point of work. The best traceability is invisible to the user because it follows the process you already run.

Steps to prepare for audits without slowing flow

You can prepare for audits without slowing the line. Start by defining a master record list that includes device history records, inspection plans, and certs. Validate that your ERP holds each record with a clear owner and retention policy. Run a mock audit once a quarter with a standard set of questions. Pull a random shipped unit and reconstruct its genealogy in minutes. Verify user permissions and time stamps support chain of custody. Align your work instructions so scanning, labeling, and sign offs match the ERP flow.

For firearms makers, review current ATF guidance for production and disposition timing and formats. For general quality systems, ensure your documented information is current and easy to retrieve. Keep a simple dashboard for open nonconformances and corrective actions so issues close fast. If you want a blueprint that fits your plant, we implement cloud ERP with built-in lot and serial tracking plus reporting that makes audits painless. For help building end-to-end traceability, contact us.